Manufacturing shutters can be a profitable business, but keeping production costs under control is essential to maximize profits. By optimizing the production process and identifying areas for cost reduction, shutter manufacturers can enhance their competitiveness in the market. In this article, we will explore ten effective strategies to reduce shutter production costs without compromising on quality.

- Supplier Evaluation and Negotiation: Regularly assess your suppliers to ensure you are getting the best prices for raw materials and components. Consider negotiating bulk discounts or long-term contracts to secure favorable pricing.

- Lean Manufacturing Practices: Implement lean manufacturing principles to eliminate waste, reduce production time, and minimize unnecessary expenses. Analyze your production process to identify inefficiencies and streamline operations.

- Energy Efficiency Upgrades: Invest in energy-efficient machinery and equipment to reduce power consumption during production. LED lighting and energy-efficient motors can lead to substantial savings in the long run.

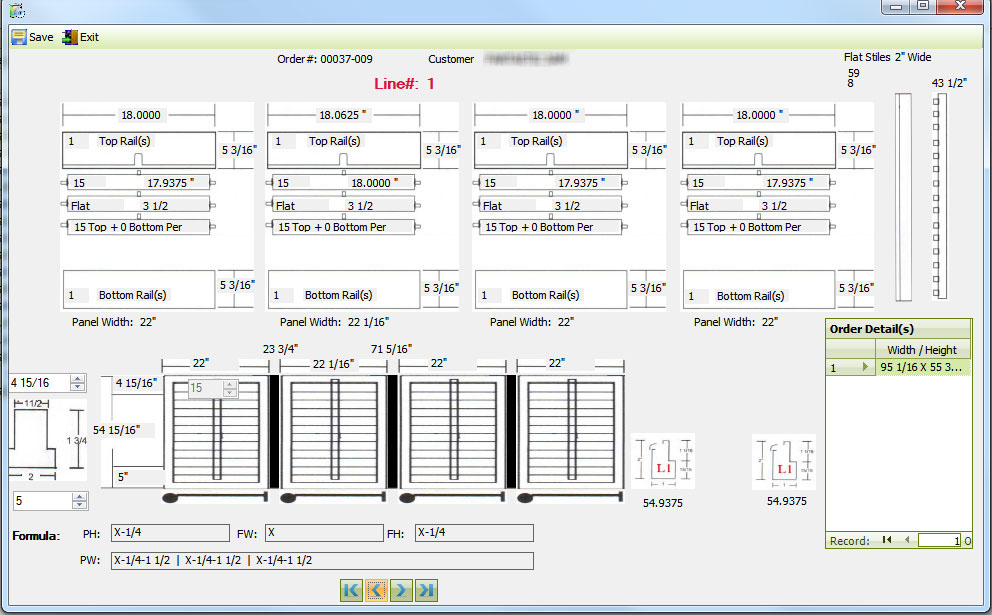

- Automation and Technology: Integrate automation technology where possible to increase production efficiency and reduce labor costs. Automated machinery can significantly improve output and reduce the need for manual labor.

- Material Optimization: Optimize material usage by accurately calculating the required dimensions for each shutter. Minimize waste by using advanced cutting techniques and recycling any leftover materials.

- Outsourcing Non-Core Activities: Consider outsourcing non-core activities such as packaging, distribution, or certain manufacturing processes to specialized vendors. This can lead to cost savings and allow you to focus on your core competencies.

- Quality Control and Rework Reduction: Implement stringent quality control measures to reduce the likelihood of defects and the need for rework. Minimizing rework helps save both time and materials.

- Employee Training and Cross-Training: Invest in training your employees to enhance their skills and productivity. Cross-train your workforce to ensure flexibility in meeting production demands and avoid downtime caused by labor shortages.

- Forecasting and Inventory Management: Accurate demand forecasting is crucial for efficient inventory management. Avoid excess stock by aligning production with demand, thus reducing holding costs.

- Sustainable Practices: Adopt eco-friendly practices wherever possible, such as using recycled materials and sustainable packaging. Emphasizing your commitment to sustainability can also enhance your brand image and attract environmentally conscious customers.

Reducing shutter production costs is a continuous process that requires diligent analysis and optimization. By employing the strategies mentioned above, shutter manufacturers can enhance their operational efficiency, improve their bottom line, and gain a competitive advantage in the market. Remember that cost reduction should not compromise the quality of your products or customer satisfaction. Striking the right balance will lead to long-term success for your shutter manufacturing business.

FOLLOW US ON SOCIAL