Shutters are not just functional window coverings; they are a testament to artistry and precision. Crafting shutters involves a blend of engineering, woodworking, and artistic finesse. In this article, we delve into the world of shutter production, exploring the manufacturing techniques that bring these beautiful pieces to life.

1. Cutting Techniques

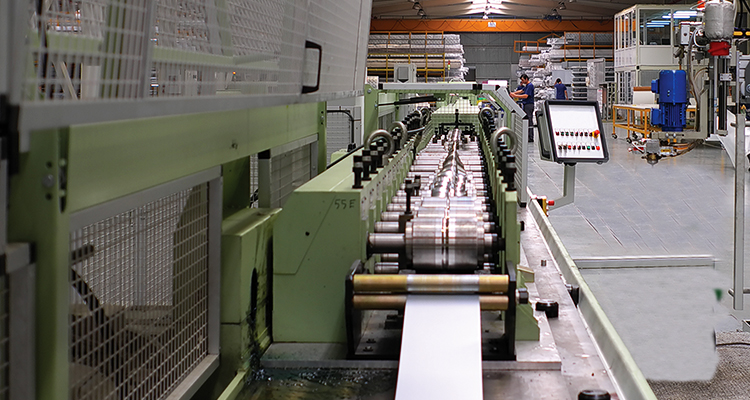

Cutting is where the journey begins. Manufacturers use precise measurements and cutting tools to transform raw materials, usually wood or composite materials, into the necessary components for shutters. Computerized cutting machines enhance accuracy, ensuring every piece fits seamlessly during assembly.

2. Shaping and Routing

Shaping and routing give shutters their distinct aesthetic appeal. Different edges and designs are crafted through precise shaping and routing techniques. Whether it’s a beveled edge for a classic look or a curved design for a more modern touch, the process demands careful attention to detail.

3. Joinery and Assembly

The art of joining and assembling components is at the heart of shutter manufacturing. Mortise and tenon joints, dovetails, and dowels are common joinery methods. Craftsmen meticulously fit these pieces together, ensuring sturdiness and longevity. The assembly stage is where shutters start resembling their final form.

4. Sanding and Smoothing

Sanding and smoothing refine the surfaces, ensuring a flawless finish. This stage requires skill to achieve uniformity across all components. It’s a crucial step before the shutters receive their final coats of paint or stain.

5. Finishing: Painting or Staining

Finishing is where shutters truly come to life. The choice of paint or stain can dramatically impact the aesthetic. Paint offers a vast array of colors and styles, while staining preserves the natural beauty of wood. Applying these finishes requires precision and an eye for detail.

6. Quality Control

Every step is underpinned by rigorous quality control. Manufacturers conduct thorough checks at each stage to ensure dimensions, alignment, and finish meet specified standards. This iterative process of quality control guarantees the production of high-quality shutters.

7. Customization and Personalization

Modern manufacturing allows for a high degree of customization. Customers can choose specific designs, colors, and sizes. Advanced machinery enables manufacturers to tailor shutters according to individual preferences without compromising precision.

Shutter production is a blend of traditional craftsmanship and modern technology. It’s a meticulous process that demands precision at every stage – from the initial cut to the final finish. The craftsmanship and artistry that go into manufacturing shutters ensure they not only serve their purpose but also enhance the aesthetic appeal of any space. Every shutter crafted is a testament to the marriage of precision and creativity in the realm of window coverings.

FOLLOW US ON SOCIAL